Over the years, one of the most consistent questions I’ve had at events and seen on social media is how much can you resize an embroidery design?

I’m always amazed at the range of answers I hear. Some will say, “you shouldn’t resize at all,” some preach safely 10% up or down, others 20%, or 30%. Some resize to the point that there is no limit…

The reality is that there is no one single correct answer because every embroidery design was digitized (or created) differently.

The home industry has been trained that one design should run well on various fabric types. The truth is that underlay, density, and pull compensation properties should change based on what the design is applied to. Leather and pique knit should not have the same recipes if you expect both to run well…

Not All Embroidery Designs Are Created Equal

To answer the question “how much can I resize an embroidery design,” we must first establish a solid foundation of the rules that govern machine embroidery. Personally, I think it would be in every embroiderer’s best interest to learn some basic theory about how designs are created and the foundational rules before they even get behind the seat and start driving.

For this reason, if you haven’t already, I highly suggest you check out our free Embroidery Digitizing 101: Cheat Sheet video course. Those of you more experienced with embroidery will agree that there is a bit of a learning curve when you first get your machine.

I sometimes feel sympathetic for sewing machine dealers when customers leave with their first machine in hand. Many of them go online and download all kinds of free designs, load them into their brand new machine, and quickly find out first hand that all designs are not created equal. The problem is that they’re so new to embroidery that they don’t understand that it’s the designs that are causing their machine to run poorly, thread breaks, and create bird nests every 10 seconds.

All the customer thinks is that “this machine they sold me is a piece of garbage”. It’s important to understand that a machine is much like our own bodies, puts garbage in, and gets garbage out! Put good stuff in, get the good stuff out!

Not all designs are created equal, which is why I always suggest embroiderers find and stick with design companies that know what they’re doing or learn to digitize and do it themselves—less aggravation, and more importantly, better results. Now, if you’re looking for quality designs, we have close to 30,000 on this site! Click here to browse our design categories now.

The most important thing embroiderers should learn first is the rules for working with the primary stitch types. All designs are essentially made up of these three foundation stitch types:

- Running stitch

- Satin stitch

- Fill stitch

Each of these stitch types has specific rules that apply to them. Just so this doesn’t become a long drawn lesson on theory, we’ll look specifically at the running stitch for now.

Running Stitch Rules:

Minimums:

There is really only one thing you can control regarding settings/properties within a running stitch, which is the stitch length. How far the needle travels between each stitch penetration. There is a minimum and a maximum. Please keep in mind that even these rules can change depending on the fabric type used. The absolute minimum would be .5mm, which means the machine would stitch every half a millimeter, which is pretty small.

We need to remember that embroidery machines like movement within the frame. If a needle stitches in the same place repeatedly, you are pretty much guaranteed to get thread breaks. Also, small stitches will assist in creating stitch intensive (or “bulletproof”) designs. This is one of the biggest culprits of poorly digitized designs, way too many stitch penetrations too close together!

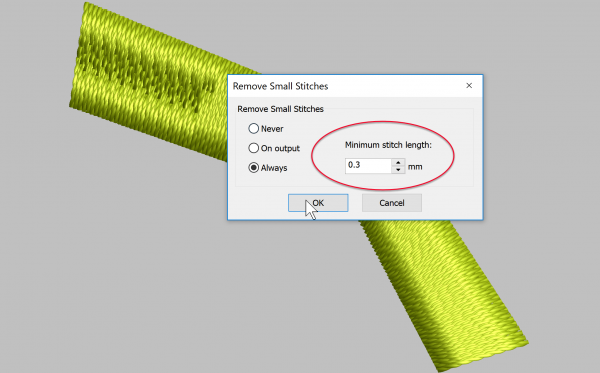

For this reason, I love Hatch software (click here to download a 30-day free trial) because it has safeguards automatically built-in. The software has a small stitch filter that automatically looks for any stitch penetrations under .3mm (default setting). When you export your design to your desired machine format, it will automatically eliminate any stitches that might cause problems.

I repeatedly hear Hatch users who’ve transitioned from other programs say: “Hatch creates designs that are so much softer than my other software did,” this is one of the reasons why.

If .5mm is the absolute smallest, then 1mm is safe, and 1.5mm is what I personally aim for when I’m creating designs.

I know a 1.5mm stitch will always embroider smoothly on my machine without creating any hard stitches. Now that we’ve covered the minimum, let’s look at the maximum.

Maximums:

Maximum stitch lengths of a running stitch is a double-edged sword as there are two sets of rules to consider: Is it wearable or a non-wearable item?

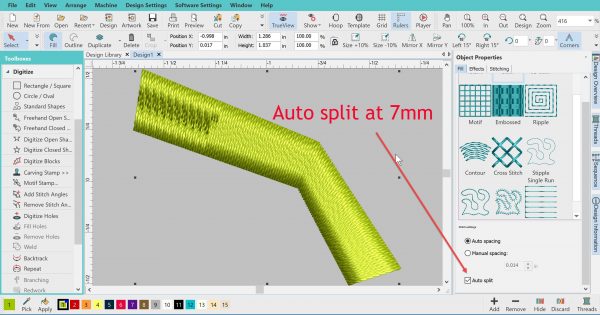

Wearable items are laundered frequently, meaning that if the stitch length used is too long, the embroidery will eventually lose its integrity and start to look worn and loopy. That maximum stitch length you’d want to use on a wearable item is 7mm. You can go longer, but it’s asking for trouble. Again, one of the auto-pilot features I love in Hatch is the Auto-Split feature. The auto-pilot feature ensures that when you have it clicked “on,” the software will automatically split any stitches that go over 7mm while you are in the digitizing process. This is an excellent feature and is again a real safeguard to ensure the user is creating embroidery friendly designs without thinking about it.

You can embroider a stitch longer than 7mm, but I’d suggest only embroidering very long stitches on non-wearable items that wouldn’t be laundered repeatedly. Most machines that have trimmers will automatically force a trim command when a stitch goes over 12.1mm in length. Your machine will actually make a single stitch and trim, stitch and trim, stitch and trim, creating an effect called invisible embroidery. This is where the machine is going through all the motions with no end result ?

How To Resize Embroidery Designs

You can see that by being armed with just the foundational rules of a running stitch, we can already assess how limitations within designs can vary. Because every design is uniquely different in how it was digitized (or created), the amount to which you can resize it up or down depends on the design itself.

I want to point out that a design usually has a much better success rate when resizing it up in size rather than down.

If a design has been digitized with very small details or very small text, the resizing odds are minimal. All you’ll do is create hard stitches and poor quality results. If an object that consists of running stitches already has a .5mm stitch length, then decreasing the overall size will cause hard stitches and potential thread breaks. As I said before, the machine will almost be stitching in the same position over and over again.

The same can be said if you have a larger design that already has many stitches at the 7mm stitch length (which is safe for a wearable item). Increase the size by just 20-30 percent, and you’ve created stitch lengths that are no longer suitable for garments. Blow the design up to double the size, and those 7mm stitches become 14mm stitches, and you now created a design that might have sections with invisible embroidery because they’ve gone past 12.1mm and forced trim commands on the machine.

So if you want to learn how to assess how much a design can be increased or decreased, you just need to learn the fundamental rules of embroidery stitches. It is well worth the time and effort to help you get past the learning curve and eliminate frustration. Over the years, I’ve developed numerous educational resources covering basic theory and explaining embroidery terminology in a way that is easy to understand. One great resource is the book I wrote almost 15 years ago called Digitizing Made Easy. It has actually sold almost 45,000 copies and is still relevant and in print. To this day, this book is used in universities across the United States to teach students studying textiles. Like many things these days, Amazon is the go-to place to order it if you’re interested.

Now, if you’re looking for faster results, I highly suggest you click here to check out our hands-on Digitizer’s Dream Course. This fan-favorite course is taught in 10 of the industry’s most popular software brands. It will get you past the learning curve both quickly and easily using proven interactive video lessons.

The Curveball: Native and Machine Formats

Now that I’ve gotten you to a place where you might be saying, ahh, I get it! I’m going to throw you a bit of a curveball.

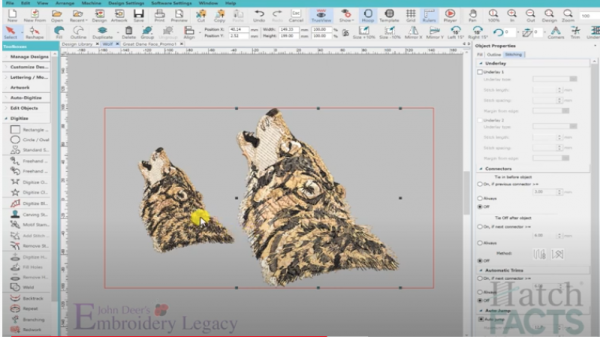

Limitations with resizing are much more dramatic when dealing with a machine file format (that you’re embroidery machine reads) compared to a native format (that your embroidery software reads).

A machine format like PES, for example, brought into an embroidery program, will have some limitations with regards to changing properties and stitch types within a design. You can edit a machine file within any software program and make changes to achieve good results. However, you do have to know your stuff, and many times you can spend more time editing a file than it would take to redo the design in the first place. Expanded and machine file formats will always have more limitations when resizing and editing your designs than native file formats do.

Now the other side of the coin is that if you have a native file format that you can load into the program, you actually own (for example .EMB and Hatch), then making changes, editing, and resizing a design becomes much easier because the software will create much smoother results. If you purchase most of the designs you run on your machine, the odds of purchasing a native file native to your own software will rarely happen. If you digitize your own designs, you must save your master files in the format that is native to your software. You will always get much better results.

Over the years, I’ve also changed the old-school digitizing technique I was taught when I first began to evolve with today’s embroidery software progression. It promotes better results, knowing that the tools I use within my Wilcom Hatch software are truly object-based. This makes embroidery files just like vector artwork files in that they can be resized beyond what you’d typically think possible.

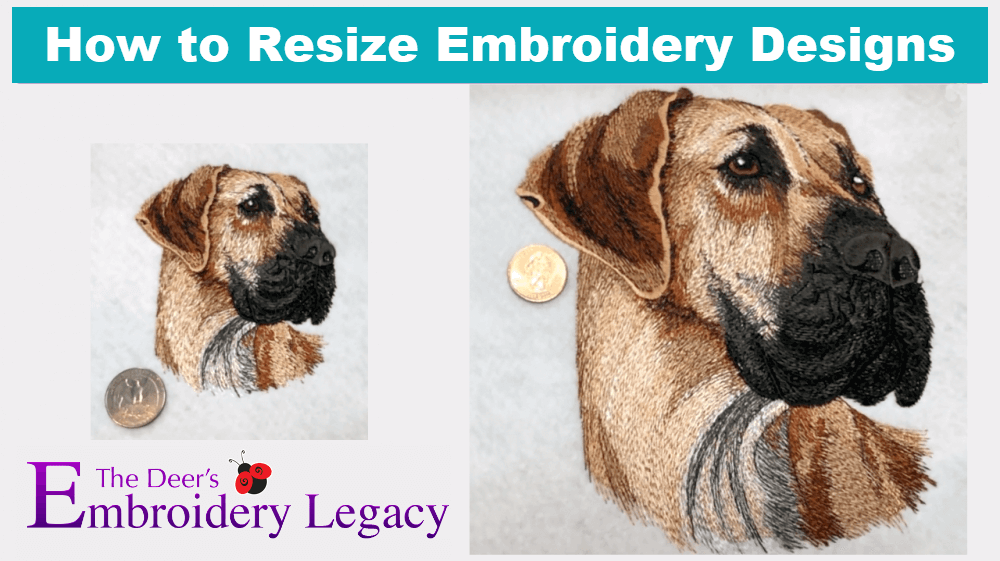

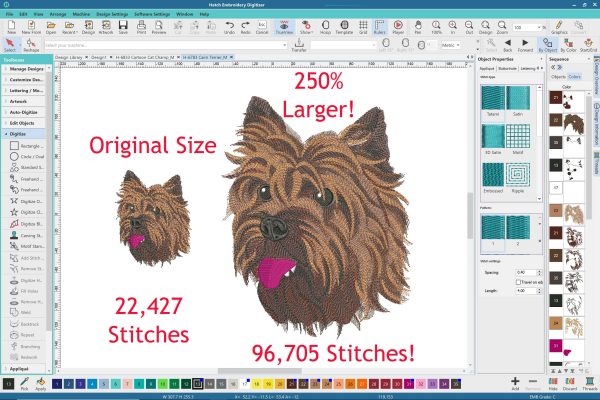

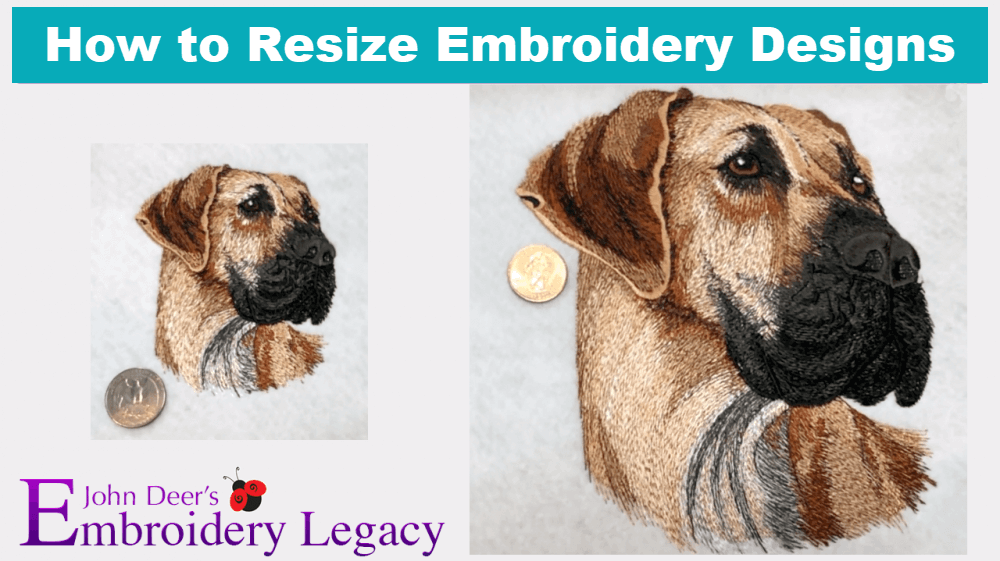

Here is a Terrier design I digitized that ended up being 4 in height and 22,427 stitches. Then I did the unthinkable, I increased the design 250%, making it over 10 in height and 96,705 stitches! The results speak for themselves.

This once again backs up that having a solid foundation of digitizing theory and the right software is the difference between having successful results or frustration on your embroidery machine.

More of a visual learner? Check out the video below

Want more great embroidery tips and tricks? Subscribe to our Youtube channel now

Conclusion: You Need Digitizing Theory to Properly Resize Embroidery Designs

In conclusion, there is no magic percentage or ratio when it comes to resizing your embroidery designs. Instead, it’s important to remember the age-old theory behind creating smooth-running embroidery designs. Follow these rules to get machine-friendly results:

Running Stitch Length Rules for Smooth Embroidery:

- Minimum Stitch Length: .5mm

- Safe: 1mm

- What I personally aim for when I’m creating designs: 1.5mm

- Maximum Stitch Length: 7mm on wearable items

- Most machines will automatically trim when a stitch goes over 12.1mm.

Hopefully, now you better understand why learning the theory behind machine embroidery is so important. I’ve always told my students that although the software has undoubtedly evolved and changed throughout the years, the age-old theory and rules behind working with thread and different fabric types haven’t. If you’d like to continue to learn this theory, I highly suggest you click here to check out our Digitizer’s Dream Course now. Even if you don’t want to fully digitize and create your own designs, learning the rules behind it will help you resize, edit, and better pick out quality designs. Truly understanding what’s happening beneath your needle will help improve EVERY aspect of your machine embroidery.

Also the type of stitch. When we create radials or ripple stitches then resize smaller it is important to look at where the highest concentration of stitches is. When you look at it in stitch view does it look like a million stars just landed on your design? Then you are going to have a birds nest or your fabric will bunch up right there.

Haha good point! Avoid the millions of stars 😉

Thanks for your advice . It reaaly helped me to understand and solve problems.

Happy to help Viviane!

This was very informative.

Thank you

Happy to hear it helped. My pleasure Martha!

This was very informative

Would love to know where to purchase the “terrier” design!

Hi Dyane, the terrier design can be found on our site: https://www.digitizingmadeeasy.com/product/embroidery-design-cairn-terrier/

Enjoy 🙂

This was very helpful! Thank you!

You’re most welcome. Glad you enjoyed it Heather!

Good lesson on resizing it was very helpful

Thanks for your feedback!

Your Provide Great Information It is Very Helpful For Me. Thank You

Thanks Stuart, my pleasure 🙂

This Article Is Very Informative For Me, Thanks For Share It

My pleasure Mark, glad it helped!

Can you let me know about when I will get this course.

Digitizer’s Dream Course 1,2,3

Thanks

Eva Patrick

Hi Eva,

First off, congratulations on ordering the complete course! You’ll be able to access the Digitizer’s Dream Course in your classroom on this site immediately after ordering: https://www.digitizingmadeeasy.com//classroom/

Please just make sure you’re logged in before visiting the URL above 🙂 Enjoy!

Also if you have any other questions in the future, please consider emailing, calling our toll free number or putting in a support ticket with us for a faster reply. You can find all our contact information here: https://www.digitizingmadeeasy.com//contact-us/

I have signed up for the Digitizing workshop May 18 and 19. Would it be helpful to take the Digitizer’s Dream Course first or would it be redundant?

Hi Bonnie, congratulations on signing up for the workshop!

It would certainly be helpful. There will be some overlap in the content found in the Dream Course & the workshop, however it would be good to be able to ask any questions you may have live if you’ve already taken the course.

Resizing designs need a lot of efforts and technique. Thanks for this informative write-up to get the required information.

My pleasure Austin!

Finally this is making sense. Thank you so much for this information. It is hard to know what size to put stitches. I have asked many instructor and I usually get “you just have to play with the stitches.” Now I am learning some really helpful stuff. Thank you again.

My pleasure Darlene 🙂

If an instructor is telling you to just play with the stitches chances are that they might not be best person to learn from. When it comes to creating or editing embroidery designs, there are certain rules that must be followed to ensure machine friendly results. Glad I could help & happy stitching!

My frustration with the Hatch software free download was that it will only show a 10% increase or decrease. Now I better understand why. I went with a different software and have not had any problems that my untrained eye would notice but if it turns out that my software is not compatible with my new machine, I will definitely purchase Hatch.

Hey Barbara, glad this article could help explain why for you 🙂

I hear you, some software brands may display resized designs perfectly on screen but always remember: the proof is in the stitching.

You’ll love Hatch, thanks for taking the time to leave a comment!

Taking your Brisbane course and just now starting to play with the program – this has helped

Hope you enjoyed our live Brisbane course Fran. Glad this article helped.

Hi John, thankyou for this education. I recently started with Hatch, and was delighted to see a number of digitised Australian birds included with the software download. But I though them a bit small, so I ‘stretched’ them (the EMB files) to a bigger size of about 17cm tall. The stitch count went up, and the designs still looked great. In fact, I thought that was probably one of them main advantages of Hatch. So I then exported the larger size designs to my machine format. I haven’t stitched them yet, but your tutorial is suggesting I need to audit the stitch quality first. Or do you think the larger ones are likely safe to stitch? Thankyou again. Lydia

Hi Lydia, the only way to see would be to run them as they embroidery files supplied within the software are from many different digitizers. Some may run better than others, any design is only as good as the digitizer who created it.

Thankyou John for the reply. Absolutely loving your websites, emails and Facebook groups. I have said this before, it is evident that a lot of work goes into the education, videos, blogs, tips, projects, etc, and so much of it freely available, it really is very appreciated, thankyou so much and greetings from Australia. One day, when the big C is no longer an issue, please visit down-under. It would be so great to have a digitising workshop here. Just a thought.

Thank you so much for feedback Lydia 🙂 we appreciate your kind words!

Thank you John for the a great video. Gave me some great tips.

I just got your courses on Bernina V7&I have V9. Are the videos just the same except for the new tools that have been added over the years?

Thank you

Regards

Caroline

Correct, the foundational tools used within the V7 Dream Course are the same foundational tools within V9

I can not login, I think something is wrong with my password and I cannot change it.

For any assistance with your account please email our office at contact@embroiderylegacy.com