Join us down a slippery slope as we learn about oil in machine embroidery! Oil is necessary for most things, from manufacturing to food to embroidery! It keeps parts moving and reduces friction and wear in our cars, door hinges, and, you guessed it, our embroidery machines!

Learn why and which embroidery machines require oil and which types to avoid to extend the lifespan of your machine. Who doesn’t want to get the best-embroidered results?

Why Does An Embroidery Machine Need Oil?

All machines, whether embroidery machines or pencil sharpeners, need lubricant. When two touching parts move, friction can damage or heat them, causing warping or distortion.

In manufacturing, there are four kinds of oil or oil-like products.

- Grease is a combination of soap and an oil-based product. The oil lubricates, and the soap emulsifies and helps the oil to remain where you put it.

- Oil lubricates and has various uses, including food, fuel, and more.

- Penetrating lubricants are thin, allowing them to reach into tiny crevices that regular oil might not reach.

- Dry lubricants are solids that can lubricate. The most common is graphite (yes, like the pencil!).

Do All Embroidery Machines Need Oil?

Surprisingly, not all embroidery machines need oil! Many embroidery machines have metal parts that need oil, but some have Teflon parts that don’t.

This is why we always recommend following your embroidery machine’s manual.

Many machines at the factory have been oiled and will not require more.

Which Parts Of My Embroidery Machine Require Oiling?

Grease and oil are the only lubricants used in embroidery machines, but oil is the only one you will use yourself. Whether home or commercial, your machine’s gears will already be greased. Only a trained technician or service person should touch it.

Before we go any further… here is the one hard and fast rule you must follow!

Check your manual for instructions on oiling your machine for commercial or home use. Only use the recommended oil.

Let’s discuss the tools you will need.

- Lint cloth: they are similar to those used for computers. Microfiber cloths are great as they are washable and reusable.

- Oiling brush or swab (cotton swab): oiling brushes are short bristle brushes often included with your machine. They allow you to deposit oil without drowning your machine.

- Soft brush: this helps whisk away lint and fuzzies. Brushes for computer keyboards also work great!

- Oil pen: usually included with commercial machines and some home machines.

- Paper towels: help protect work surfaces.

Where Are Machines Oiled?

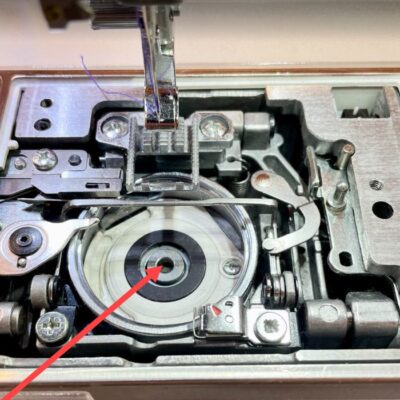

Generally speaking, embroidery machines require oil on the main moving parts: the bobbin case, the needle bar, etc. If there are Teflon or nylon parts, those will not require oil since Teflon against Teflon is slick enough.

- Home machines are oiled every one to three months, depending on how heavily they are used.

- Commercial machine oiling goes by hours of operation since they are often used eight to twelve hours a day. A heavily used machine will require some parts oiled daily, some areas weekly, and some monthly. There are generally ports that are marked to remind you.

Commercial machines have all the oil ports labeled, and different parts require lubrication at different intervals. The bobbin, for example, should have a drop of oil each time you put in a new bobbin, but the main shaft requires lubrication less frequently. You’re service technician or user manual will guide you on where and how often to oil.

How Do I Oil My Embroidery Machine?

Not sure how to oil your machine?

Hey! It happens to us all at one point whether you got a new machines or are beginner embroiderer. Many of us need guidance; your service center or machine technician are great sources. You can watch videos online, but your machine manufacturer will produce the most helpful ones. Many sewing centers have classes and tutorials if you ask.

Be sure to always follow your manual, but here are the steps generally taken to oil a machine:

- Unplug your machine.

- Remove the needle, throat plate (if instructed), and anything preventing access to oil points.

- Using a soft brush, gently brush away any visible lint or fuzzies. Avoid using compressed air as it can push dirt and lint further into the machine, making cleaning difficult. Do not use a vacuum… this can create static, damaging the electronics on your machine.

Learn more about the best-kept secrets on maintaining an embroidery machine to keep reliability up and costs down.

4. Use a pen or brush to oil your machine. Pens are best for commercial machines. Look for marks showing where to put oil drops and how many to use. On a home machine, use your oil brush or the pen (if needed) and put a small amount of oil in the places indicated.

More is not better….

Oil lightly and reapply if necessary rather than drown the area with oil. This will create oil stains on your embroidery.

- Rotate your machine to deposit oil.

- Wipe away the remaining oil or any dust dislodged during oiling using a soft cloth or paper towel.

Oils For Embroidery Machines

Good Oils

We don’t want to sound like a broken record, but please consult your manual or use the oil that comes with your machine. Any reputable machine company will also have oil for sale should you ever run out.

Sewing machine oil is the recommended type of oil. You should never use these oils.

- WD40- this is a water-displacing lubricant which is short-acting.

- Motor oil – no explanation needed. It is not a motor, don’t use it.

- Salad oil. No.

- Silicone – different than regular oil; it is synthetic and usually used for plastic parts. Remember that not all plastic parts need lubrication. Use the right type if they do, as some chemicals can melt plastics.

Bad Oils

Here is an easy list of don’ts:

- Don’t use non-recommended oil

- Don’t over-oil

- Don’t use solvents or chemicals to clean oil

- Do not purchase a large quantity of oil, regardless of how good the offer may be. Instead, opt for a smaller size and replace it more often.

Conclusion

Oiling and lubricating your embroidery machine is necessary for being a good embroiderer. Your machine depends on you to keep it running smoothly; oiling is an easy part of your maintenance.

Always read your manual, work safely and cleanly, and get help if unsure. Consult your sewing center or ask your technician to teach you how to maintain your machine properly. It will thank you and repay you by stitching well throughout the years!

P.S. Don’t forget to download your free Embroidery Legacy Design Kit for 11 fan-favorite designs!

Thanks for this information!! I can count on The Deer’s Embroidery Legacy to keep me informed about machine embroidery! I love the continuing education I get watching videos and reading posts!

We love hearing feedback! We appreciate your support Elaine 🙂

This is so informative. I have been using my machine about a year and need new oil. Glad you could steer me in the right direction! I always depend on you for the best and easiest to understand information and problem solving!

Thanks Diana! Appreciate your support

thanks for the tips on oiling the machine. Always a good reminder to not overdue

Any time Marilyn! Thanks for reading