You’ve heard of push and pull compensation in machine embroidery, and you know it’s essential, but when someone talks about it, do you feel like they’re explaining rocket science to you?

It can sound confusing, but it’s really not! We’re here to help explain! Whether you’re a beginner or an experienced digitizer, learning theory is critical to producing quality stitched out embroidery results.

There is a general rule in digitizing a design: What you see on screen isn’t what you’re going to get when the design sews out! In fact, if the design looks perfect on screen, you can almost bet that it won’t sew out properly.

What is Push and Pull Compensation In Embroidery Digitizing?

Since the early days of embroidery, all machines have created stitches in the same manner. There is a top thread and a bobbin thread which both have tension. Once both these threads intersect with the timing of the machine’s needle scarf and bobbin hook, they pull on each other to create a flat stitch.

Without tension on both the top and bottom threads, the embroidery would not sit flat and have a loose and loopy appearance. This is known as embroidery distortion and occurs due to tension issues on the embroidery machine.

Distortion happens because of how the top and bobbin threads react to each other when applied to different fabric types. The name of this reaction is most commonly referred to as “push and pull compensation.”

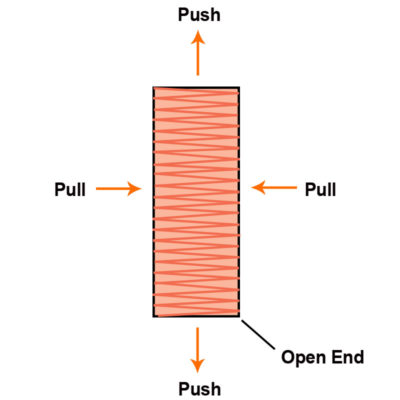

I like to use the analogy of squeezing a tube of toothpaste. When pressure is applied, the toothpaste comes out of the open end at the top. This is exactly what happens to stitches on your machine.

Stitches in a satin column have a pulling effect, making the column slightly thinner when it sews out. The open end of the satin column, which is any that you could slide a pin under, is where the push effect will come into play. When push and pull come into play, the width of the thread and the density of the stitches distorts the fabric.

Are you more of a visual learner? Watch our YouTube video below as John dives into push & pull compensation in embroidery digitizing.

Pull Compensation for Embroidery Digitizing

Pull compensation is a tool that is built into your embroidery software. When it’s activated, your software will overthrow the width of the column stitch.

With most software programs, you’re able to control the amount of pull compensation you want for the designed object you’re digitizing. You must understand when and why you need to adjust this setting.

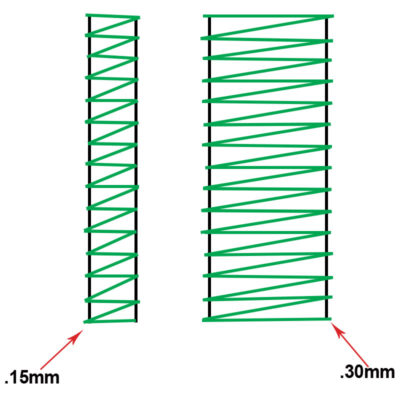

The rule of thumb is, the wider the stitch, the more pull compensation you need to apply. Why? Because the wider the stitch is, the more the tension of the top and bottom threads will increase to create a flat stitch on the fabric.

The image above shows how as the column width increases, you also need to increase the settings for the pull compensation. You’ll notice that a 2mm column width has only .15mm of pull compensation applied and will incrementally increase to the point that the 7mm column has a .3mm of pull compensation.

The wider the stitch, the more pull compensation you’ll need to apply. Please keep in mind that these rules are not set in stone. Another factor that will affect the amount of pull compensation is the type of material being embroidered on. As an example, denim will require much less pull compensation than stretchy terry cloth.

Pull compensation is an excellent tool within your software because it makes digitizing much easier if you understand the theory behind it. In the days before software, we manually overthrow every stitch to adjust the column width. I remember it being a very tedious process.

Push Compensation for Embroidery Digitizing

The “push” that occurs is, unfortunately, something that the software does not control automatically. The trick for learning how to control the “push” takes a bit of time and practice to grasp and is largely tied into digitizing at a consistent scale.

For this reason, and if you haven’t already, I highly suggest you click here to check out my Digitizer’s Dream Course. It’ll teach you my “golden rule” for digitizing designs at scale and how to master applying for proper push compensation by interactively creating designs yourself.

When you manually adjust “push compensation,” you need to cut or pull the object nodes back a bit into the direction of the stitches being created.

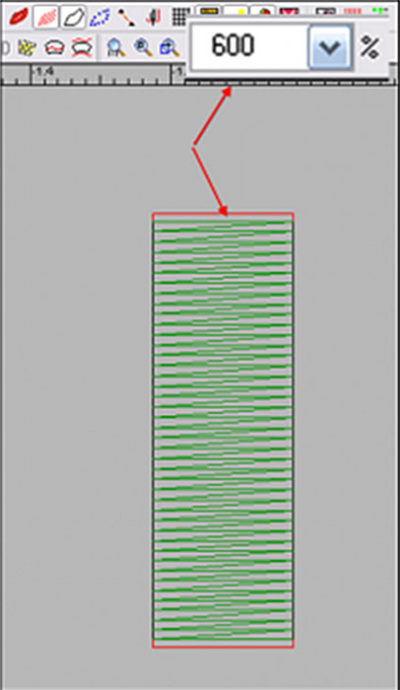

So the question is, how much do I cut back the node of the object from the open end while I’m digitizing on screen? Usually, the rule is you want to place your inputs about one stitch short (approximately .4mm) from how the artwork appears on the screen.

By digitizing at a consistent scale, the amount you cut short always stays the same, and you won’t be guessing as you would if you were constantly zooming in and out at different scales on screen.

Like most of the rules associated with embroidery, this rule can change in different circumstances.

For instance, let’s say you are creating a satin stitch and then placing a running stitch around it to create the effect of an outline in a different color. In this circumstance, you would cut back the satin stitch nodes by two stitches (approximately .8mm) and then digitize the running stitch, placing your running stitch points exactly to the artwork.

If you cut back the satin stitch too much, you might see a gap between the two colors of stitches. That satin stitch thread might extend past the running stitch and look like mistakes if you don’t cut it back enough. Again, much of this is covered more in-depth in our Digitizer’s Dream Course, but for now, please understand that there is no one size fits all approach to every design you plan to create.

Practice Push and Pull Compensation Yourself

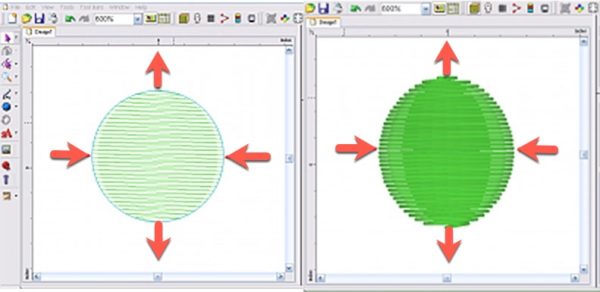

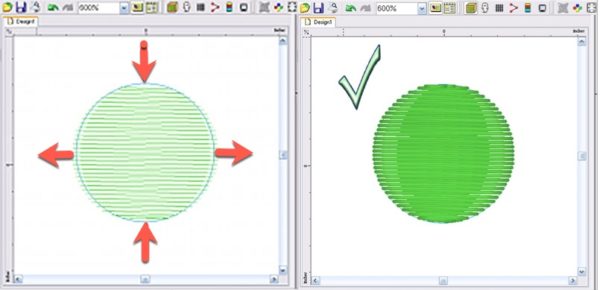

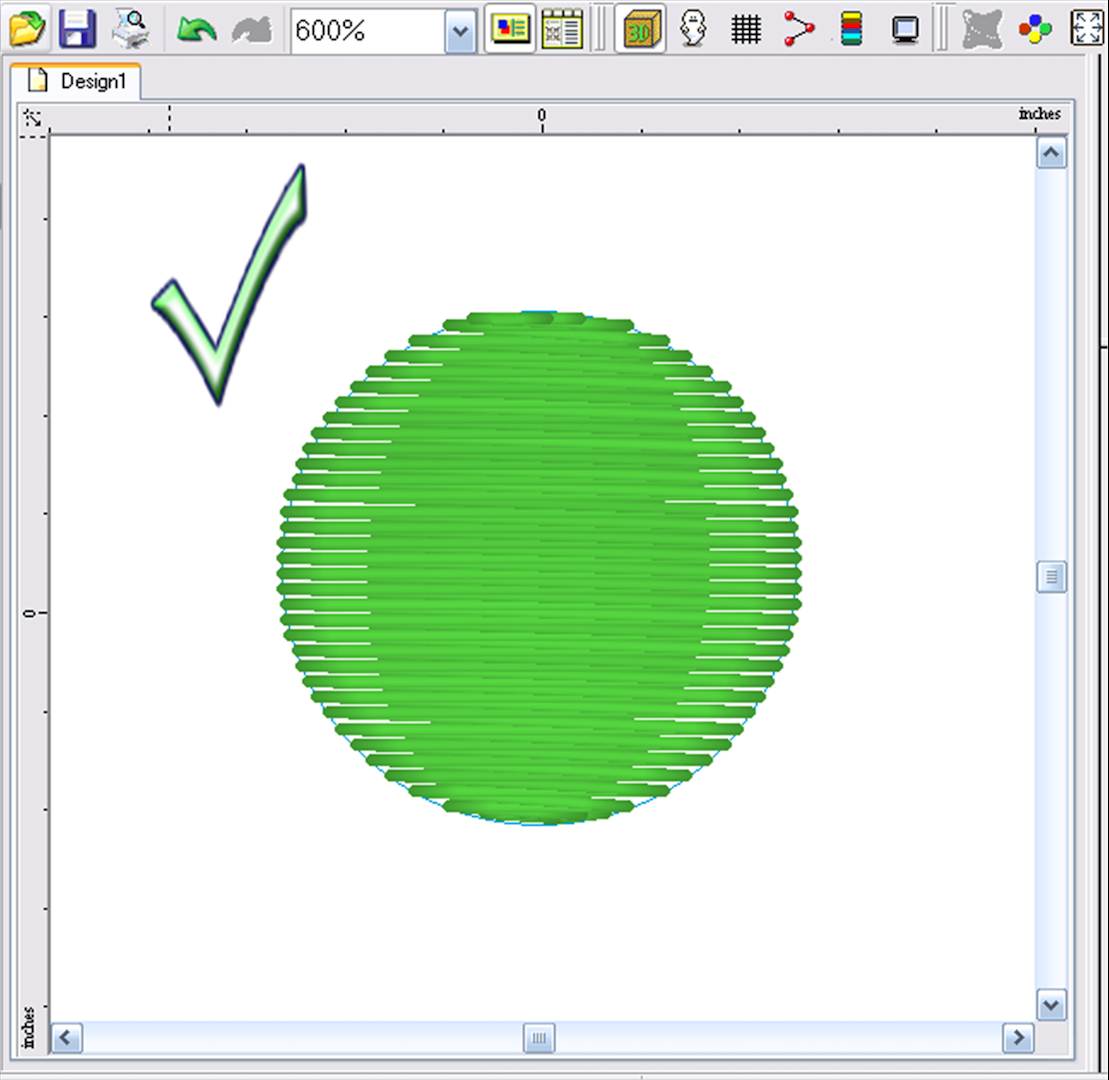

One of the easiest exercises to practically understand push and pull compensation is to digitize a perfect circle using a long satin stitch.

Remember: the longer the stitch, the more it pulls. First, digitize your points following the artwork exactly; you will see a perfect-looking satin stitch circle on screen. Now take this design and run it on your machine; the result will be an object that stitches out looking like an egg! The embroidery has distortion because of the push and pull compensation.

Now I want you to digitize the circle again. This time I want you to cut back on the open ends on the top and bottom and exaggerate the points on either side of the direction of the stitch. On screen you’ll see what looks like a sideways egg; now, when you run this file on your embroidery machine, guess what? It will stitch out looking like the original artwork, and the result will be a perfect embroidered circle.

Push and Pull Compensation in Action

One of the easiest ways for me to see if a digitizer understands push and pull compensation is to examine the lettering they have digitized. I’m not talking about keyboard text or fonts that are built into your software or machine.

If you don’t use the push and pull rules when creating lettering, you end up seeing text that looks very sloppy and uneven. We call it a dancing baseline. This is when all the letters look uneven, and some appear larger and smaller than others. The point is, you can’t digitize the text exactly the way you see them on your screen. The letter “L” has two open ends, a “T” has three, a “P” has one, and an “O” doesn’t have any.

This is the reason why the majority of software keyboard lettering sometimes works and sometimes doesn’t. What people forget is that someone physically digitized that font in the first place.

Depending on the software they used, it could just be an embroidery font that is made up of stitch files that have been converted to keystrokes (like font packs sold as stitch files or the majority of the keyboard fonts out there). When those types of fonts are resized, they tend to lose their visual integrity quickly.

Any created font is only as good as both the digitizer and the software they use. If the digitizer is inexperienced and hasn’t correctly applied the push and pull rules, then it goes without saying that the quality of the embroidery design will be compromised.

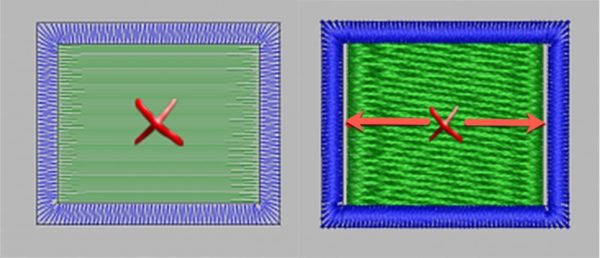

Push and pull will affect fill stitches more dramatically because fills are used for covering large areas—the larger the area, the more stitches.

The more stitches, the more the design will distort when applied to fabric. This is usually why digitizers will try to put a satin stitch border around a fill area, to compensate for how a fill can distort an object. Even when you digitize a fill with a border, you should still make “push and pull” adjustments for the fill before you digitize the satin stitch.

In the example below, no compensation or overlap was applied to the fill area. The result is poor registration: you can see the fabric showing between the two stitch types because of the pull.

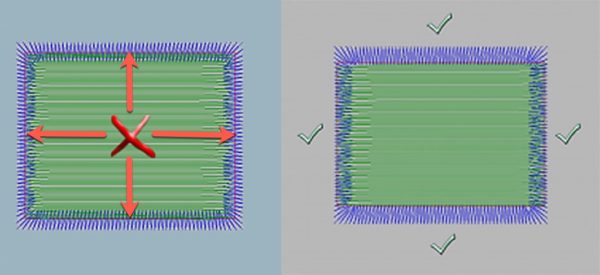

Now, look at the next example. Even though it’s overlapping about halfway around the satin stitch, you could experience the same problem as the first example if you are embroidering on sheer fabrics or fabrics with a lot of stretch.

In this last example, you can see how I exaggerated my overlap to coincide with the direction of the stitches and cut back the shape in relation to the open ends.

My nodes on the open ends line up to the bottom of the satin stitches. I know there will not be any gaps where fabric shows through. The laws of “push and pull” assure me that the top and bottom “push” will fill in the blanks. I’m also exaggerating the fill almost to the outer edge of the satin stitch, which means I’ll be safe no matter what type of fabric I want to use.

With regards to satins with running stitch borders as well as fills with satin borders, the key to success is always to keep the outlines and borders true to the artwork. Always adjust the “push and pull” compensation with the stitches that are on the inside.

Knowing Digitization Theory Improves Your Embroidery

Are you interested in becoming a better digitizer or embroiderer?

Check out our free Embroidery Digitizing 101 Course by clicking here. In this free brief Digitizing 101 Course, John covers the theory for creating embroidery designs. The theory he talks about in this video is the foundation you can incorporate with any embroidery software.

Combining theory with software is key to creating beautiful designs. Knowing the theory behind your embroidery will make you a better embroiderer and show in your stitched-out results.

This Digitizing 101 Course will provide you with the basic foundation of the terminology involved with digitizing and embroidery designs. When problems happen within your embroidery, you’ll better understand why and how to fix them. This video cheat sheet covers topics including what digitizing is, stitch types, density, underlay, distortion (push and pull compensation), registration, pathing/mapping, color changes and trims, and fabric assist.

To make things easier, we’ve also included a printable PDF sheet with diagrams and notes so you can refer back to it when needed.

I highly recommend checking out this free Digitizing 101 Course whether you’re a beginner and just learning or an experienced digitizer and need a quick refresher! Click here to learn now.

Conclusion: Proper Push and Pull Compensation Is Essential To Quality Embroidery

Now you know more than most about how and why push and pull compensation works within an embroidery design. The next step is to practice and apply what you’ve learned!

Our Digitizer’s Dream Course is an excellent resource to help you put this into action by digitizing a variety of specially chosen designs with the artwork I provide for you. It’ll also dive further into vital embroidery digitizing theory and explain the secrets of digitizing at a consistent scale. Simply click here to learn more and improve your digitizing results now.

If you’ve enjoyed this article or found it helpful, please let me know & leave a comment below. Or, if you have a question or a comment that might help others looking to learn more about push & pull compensation, I’d love to hear your thoughts!

Happy stitching!

P.S. Don’t forget to check out our free Digitizing 101 Course by clicking here to learn about digitizing theory that can be applied to any embroidery software!

Just read your Push and Pull article. It is the most in depth piece I have found in all my years of “studying” digitizing. My problem is “how do I erase all previous information from my brain”. When I get a new design, first I dissect the design to see how it is put together. The one thing I could not figure out was the push and pull aspect. I do not have Hatch, but am evaluating Hatch versus Bernina V8.

Keep up the informative articles, I definitely will be looking for them.

Thank you John for this instructive narrative on Push and Pull compensation. When I first decided I wanted to learn how to begin the journey to digitise, I watched your YouTube videos and bought your book! It is only now after two years that I begin to understand more clearly what you were saying and because of your wonderful way of teaching I bought Wilcom Hatch software. In conjunction with your digitising lessons it was like being back at school learning about a subject that I have come to love. There is still a long way for me to travel, but I like every mile I take. So thank you very much for all your support and sharing your knowledge.

Hi Gill, so happy to hear you’re enjoying your embroidery digitizing journey. There can be a learning curve, but it certainly is rewarding.

Thanks for the kind words and for supporting us over the past few years.

Keep up the good work & happy stitching!

Great article, great examples. I agree with Kaye, now to relearn the proper way. I also have Benina V8 and Melco DS 10 but love the features built into your software when breaking apart designs or reselecting the color sequence for stitching. I have watched all your videos, but I’ll leave the digitizing to you

Thank you Marianne, glad to hear you’re enjoying the videos.

Sounds like you’ve got a grasp on editing with your software which is half the battle.

Thanks for commenting & happy stitching!

Wow…I consider myself very computer literate. I use Florian (RIP Walter) FTCU and have a Bernina 700. I have been so thankful to have found your website and videos! The most complicated software I’ve ever used is video editing. But this embroidery thing is way more complicated!! The amount of variables seem limitless which is what I believe makes it so challenging to learn. Thank you John for the Push/pull explanation…the fun part about embroidery for me is not only the end result (hopefully a beautiful stitch out) but the ability to create something that is very unique and that you can say “I made that!” I have so much to learn but I find the embroidery community to be a special group of people who are very willing to help other embroiderers. And your teaching style is so good in that you are patient and almost calming in your delivery. Thank you and I look forward to learning as much as my brain will absorb!

Hi Bill,

Thanks for the kind words. So happy to hear you’re enjoying our education.

There can certainly be a bit of a learning curve when it comes to embroidery software, but that’s why we’re here to help.

Sounds like you’re on the right path. I agree, there really is nothing like looking at a project and saying “I made that”. Keep up the good work and thanks for commenting!

Amazing explanation thank you!! In regards to how much you should compensate, is it universal to all stitch types, to should cut back 2 stitches when adding an outline after (for push comp) or is this only for satin stitches with an outline (not fills) additionally, does this amount also change based on fabric type? if so which fabric is recommend for the 2 stitch comp?

Hi Nicole, fully understanding the specifics of push and pull compensation in relation go fabric and stitch types is not a preset recipe, which is why the art of digitizing will take time and practice. We give a solid foundation for starting the process, then it is continued learning and practicing.