Did you know that roughly 80% of profit-making embroiderers digitize on caps? Caps are not only a staple of the embroidery business, but they are also among the many clothing articles we embroiderers get to have fun and be creative with. Why not take the time to learn how to embroider on them, whether for business or pleasure?

Generally speaking, embroidering on beanies or toques is similar to embroidering on any other piece of fabric, so this article will specifically narrow in on embroidering on caps.

This article will teach you what you need to know to embroider on hats and caps properly. We will discuss:

- Cap and hat terminology

- Different hats for embroidery

- How to embroider a cap hat (placements, stabilizers, tips, etc)

- How to properly hoop cap hats

- Digitizing tips to give you the best-embroidered results.

Let’s dive in!

Cap & Hat Terminology for Embroidery

Crown

-

The cap’s crown is made up of 4, 5, or 6 panels. The most common configuration is the 6-panel cap commonly found in baseball caps.

Visor

-

Also called a brim, bill, or visor. These can be flat with squared-off or round shapes or curved. Generally, it is a piece of plastic or cardboard covered in fabric. This is then stitched with decorative stitching to help keep its shape. Embroidering on the visor is a careful process. Please consider your machine before starting a design on the visor.

Button

-

The button holds the panels together. It can be metal or plastic, which has been covered with fabric.

Buckram

-

Is the backing you see on the reverse of the front panels. This stiffens the twill fabric and gives a solid base for embroidery. Buckram is a cotton fabric stiffened with a stabilizer, but it can also be made of plastic mesh. When using the caps with plastic mesh, use less dense designs as these can create bullet-proof areas which can break thread or needles.

Sweatband

- The sweatband that surrounds the cap’s inside absorbs moisture and protects the outside from stains. When embroidering, make sure to turn the band back, so you are not embroidering over it, as this will make the hat uncomfortable, reduce how well the band works and create very dense areas.

Eyelets

- Are the small embroidered holes on the top of the cap. These are for ventilation but can be excellent guides for your embroidery placement.

Closure

- Closures can come in an adjustable buckle, such as velcro. Some fitted caps come pre-sized and do not require an adjustment. The curved opening in the rear of the cap is a great place for names, teams etc. These are wonderful selling points.

Choosing Your Cap Hat for Embroidery

Ball caps are all about variety. You look at a cap catalog or website and there are hundreds if not thousands of choices. You have your choice of color combinations, material, the height of the crown, type of bill, back closures and the list goes on and on. While there are hundreds of different hat styles and manufacturers out there, most hats generally fall under 3 main categories:

1. OPF (One-piece front) hats for embroidery

OPF usually categorize as “trucker/farmer” hats. These hats have one piece of foam laminated backing (gives the hat structure), and the rest of the hat is more of a mesh material. OPF hats are usually pretty easy to hoop and embroider because of their laminated backing, and there is no center seam in the hat.

2. Varsity/collegiate hats for embroidery

Varsity hats tend to fit a little closer to the head because they do not have any laminated backing (structure) on the front of the panel. Because of this, these hats do tend to move a little bit, which is why making sure hooping is done properly is so important.

3. Sports caps for embroidery

Sports caps are generally the most popular style of hat, especially for embroidery. This hat has a center seam down the middle of the front panel (Aka: the Bermuda triangle of embroidery. You generally tend to lose stitches in the center seam) and a laminated backing giving it structure.

How To Embroider Cap Hats

When embroidering caps, there are various placement options. Some options are limited to embroidering before manufacturing (for example, the bill). But there are plenty of options for an embroiderer to consider. Most multi-needle embroidery machines can handle the front, both sides, the back of the cap, and even most places in between.

It should be noted that embroidering a hat on a single-needle or flatbed machine is extremely difficult. You will need a cap frame & preferably a multi-needle embroidery machine to easily embroider caps. If you’d like to learn more about which machines we suggest, check out our What is the Best Embroidery Machine for a Home Business article.

The most common area embroidered is the front of the caps. Even the most basic cap frames are designed to do the front of caps. Today, most commercial embroidery machines utilize wide angle cap frames designed to go most of the way around the cap, typically 270º of rotation. This will handle not only the front of the caps but also the sides. That leaves the back, for which most embroiderers use a traditional round hoop.

Here we want to look at each location and see what needs to be done for the best results. While the cap’s makeup does play a big part in how each cap is framed, the basic principles will work regardless of the type of cap. Let’s start with the front and center.

Machine embroidering the front and center of hats

The front of a cap is the most common placement and probably the easiest placement to sew. As mentioned, all cap frames are designed to embroider the front of the cap, if nothing else. The main variance with ball caps is whether or not the front panels are structured or not. Structured caps typically have a fused buckram backing inside, making the crown of the cap stand up. Unstructured (varsity & collegiate style hats) do not have this and tend to be more floppy.

For unstructured caps, it’s important to use cap backing (stabilizer). Cap backing is a stiff and heavy tear away. It provides stabilization for the fabric for unstructured caps and helps hold the shape of the cap while it’s embroidered. Structured caps don’t need the backing as the fused buckram acts as the stabilizer.

Then you have some in-between styles like soft buckram or even foam-backed caps. For caps like these, using a piece of cap backing is recommended and yields excellent results.

When doing front only placements on structured caps, it’s not always necessary to put the back clip on the frame of wide-angle caps frames. In fact, for larger designs, it’s often advantageous to leave the back clip off for these types of caps. It gives a little flexibility to the cap and prevents distortion of the design at the top of the design.

Machine embroidering the side of hats

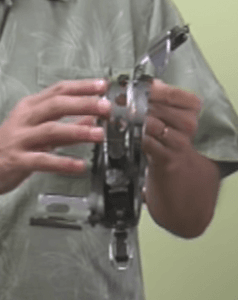

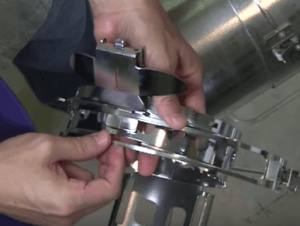

For side placements, you must utilize the back clip. The primary purpose of the back clip(s) is for side placements on caps. Wide-angle cap frames vary from brand to brand. The main difference is the back clips, as some have one large clip or one on each side of the back. Most brands use multiple clips that look a lot like binder clips from an office supply store. Whatever the type of clip, it’s important to use them when sewing side placements on caps. Otherwise, the design will look like it’s running downhill.

While cap backing may be optional for front placements on certain caps, it’s a necessity for side placements. There is no fused buckram on the sides of caps and, therefore, must be stabilized. For normal twill caps, a single piece of cap backing will work just fine.

Tip: Flexfit and other stretch-to-fit caps require at least 2 pieces of backing, if not a cutaway backing.

The same goes for a mesh cap. Yes, it’s possible to sew on mesh caps with the proper stabilization. The backing provides the necessary material to hold the stitches together. For this reason, we recommend a cutaway stabilizer.

It can sometimes be tricky to get the backing to stay in place on the side while hooping the cap. The tendency would be to tuck it under the frame. While that holds it in place while on the framing device, the backing will fall right out afterward as it is not being held in place by the frame. The cap has to be hooped with the backing on top of the frame.

One way to overcome this hassle is by placing a piece of double-sided tape (such as carpet tape found at most home improvement stores) on the side of the cap frame. Then peel the backing paper off and stick the cap backing onto the tape. This will secure the hold the backing in place long enough to get the cap hooped but pulls off easily from the frame.

If you’d like to learn more about different stabilizers, when and where to use them, check out our Complete Guide to Machine Embroidery Stabilizers by clicking here.

Embroidering the back of hats

Placements on the back of caps are relatively straightforward. There are several attachments on the market to assist with this placement, but a simple solution to cap back is to use a conventional small round hoop. Most machines come with a 12cm or 4.5 round hoop, which is the perfect size to fit the back of a cap, especially those with openings. The back of a cap can be hooped on a table corner if necessary, eliminating the need for any special hooping devices.

To align the back, use the marks that are typically molded into the hoop. The center seam aligns with the marks at 12 and 6 o’clock. The edge of the opening aligns with the other marks.

To stabilize the back, be sure the piece of backing covers the entire hoop. The cap back will not cover the whole hoop, but it needs to cover the whole hoop for the backing to provide great stabilization.

How to Hoop Cap Hats for Embroidery

Subscribe to our YouTube channel now for more great embroidery tips & tricks by clicking here!

To start embroidering on your hats and caps, they will need to be hooped properly. Whether you’re new to embroidery or an experienced embroiderer, I’m sure we can all agree that hooping caps can be difficult, especially without proper instructions. I frequently see people post about their failed embroidery hat projects, asking what went wrong, and often end up blaming their machines. Little do they know that if their cap isn’t hooped correctly, it can lead to disastrous results. As with any embroidery project, if your hooping isn’t clean, your embroidery won’t be either.

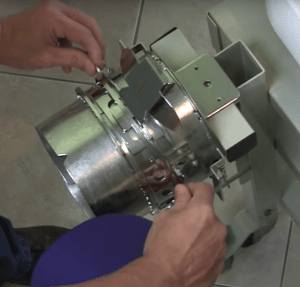

Let’s go over a hooping technique for caps/hats that the Embroidery Legacy used on our caps while running two of North America’s largest embroidery production factories in the 1990s. Follow these steps to ensure your cap is hooped properly. Before we get started, it’s important to understand that you will need a cap hooping accessory. This accessory consists of 3 main components:

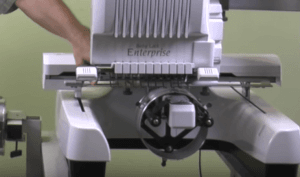

- Driver: the driver fits right over the top of the arm of the machine.

- Cap frame: the cap frame is what your hat will be attached to.

- Jig: the jig attaches the cap frame for more accurate hooping.

1.Driver: the driver fits right over the top of the arm of the machine.

2. Cap frame: the cap frame is what your hat will be attached to.

3. Jig: the jig attaches the cap frame for more accurate hooping.

How to hoop your hat:

Reminder: One of the most important things to remember when hooping your cap is that the center seam of the hat lines up to the center mark on your cap frame.

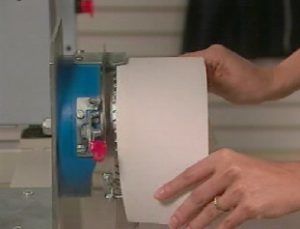

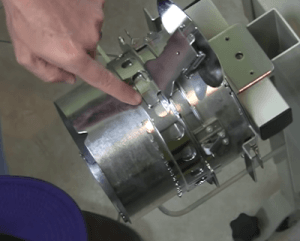

Step 1: Making sure your cap frame is properly secured to the jig. You will know it’s secure because it will click into place and will have no, to hardly any, wiggle room.

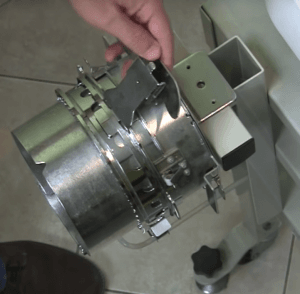

Step 2: We want to get the cap frame into position for our hat. We’ll start by moving the peak mount out of position as well as the band.

Step 3: Now that the jig is ready for hooping, we need to prepare the hat itself. We’ll start by moving the band on the inside of the cap out of the way, as the band will be placed underneath the plate on the jig. (Be sure to try and align the red line to the center seam)

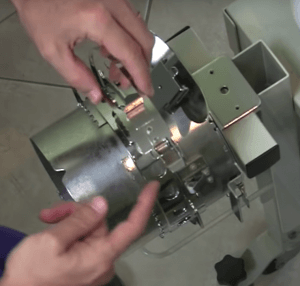

Step 4: As our hat is on the cap frame and the band of our hat is securely in place, we’re going to take the cap frame band/strap and secure it so the teeth of the band lines up to the base of our cap. Once in position, push the strap down to lock it. Be sure there is no excess space where the peak of the hat meets the crown.

Step 5: For our final step, we’re going to start by placing material over the peak of the hat to avoid unwanted markings on our cap (hats are generally one of the hardest materials to get hoop burn out of). Once the material is in place simply engage the peak mount to ensure the peak of the hat won’t hit the machine while it’s embroidering.

Your hat is now successfully hooped.

Embroidery Designs for Hats and Caps

Always remember, a hat needs to be hooped properly to run successfully on a machine. But what is equally or even more important is that the embroidery design is digitized specifically knowing that it will be embroidered on a curved surface.

Designs need to be digitized specifically for caps for best results. Most experienced digitizers will take into account a design that is size friendly for a finished hat and digitize it accordingly.

Digitizing Embroidery Designs for Cap Hats

If you don’t find the design you’re looking for or don’t want to spend the money outsourcing your designs, why not digitize it yourself? If you’re unfamiliar with embroidery digitizing, check out our What is Embroidery Digitizing Article.

When digitizing designs for caps and hats, there is one rule you should always follow.

The rule when it comes to digitizing caps: always start bottom-up and center-outward.

You always want to start digitizing from the bottom up (from the peak of the hat, up to the crown); otherwise, your stitching will buckle over, and you will get poor results. You also want to start digitizing from the inside out (start from the center of the cap and proceed outward), ensuring no buckling will occur.

There are many other things to consider when digitizing a cap, such as changing the underlay, why you need to overlap satin stitches, fixing hat embroidery designs, separating and gaps between objects, and sew much more.

To get answers to all these questions and more, check out our Youtube video tutorial on digitizing hats and getting help with your hat embroidery. Click here to watch now.

Although the front of a cap is usually most popular, what about when you want to digitize the back of a cap? You want your lettering to line up just perfectly, but with different styles of hats, what can be done? Watch the video below as we explain a few simple steps to follow so you can create a template and create your perfect design.

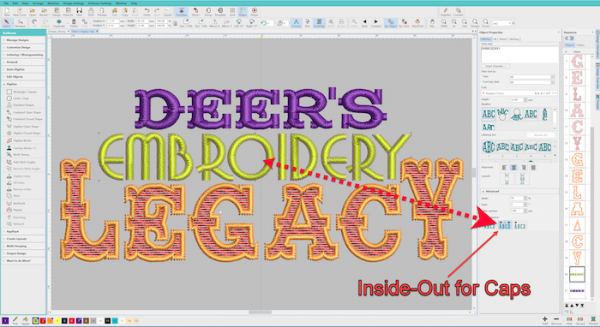

Which embroidery digitizing software can I use with hats?

If you’ve researched digitizing software, you’ve probably come across Hatch embroidery software. We strongly believe Hatch is the best embroidery digitizing software for the home embroidery industry. It has multiple features, an easy to use interface, and has a great price point. If you are looking into embroidery digitizing software, I highly suggest you check out our What is the Best Embroidery Digitizing Software article.

We always tell our customers to try before you buy. For a free 30-day trial of Hatch software, click here. You’ll see why thousands of embroiderers world-wide love this software, as the quality of the software and support will speak for itself.

If you’re interested in purchasing Hatch embroidery software, be sure to purchase through Embroidery Legacy to experience our quality support and receive our exclusive bonuses (worth an extra $235!). Click here to find out more about our exclusive bonuses.

Remember how I said Hatch has a ton of cool features? Well, if you’re using Hatch embroidery software, there is a feature I suggest using to help make this process easier. Under the “lettering” properties, use the “inside-out” feature when creating designs for caps. It will automatically create your design inside-out; this will help prevent buckling and give you the best stitch out results possible.

Check out our video below as I show you how to layout a design using only ESA keyboard fonts, so it is machine-friendly for finished caps. I’ll also briefly cover the “bottom-up” and “inside-out” embroidery digitizing rules. Plus just to be sure nothing is traditional, let’s throw a bit of “Mylar Magic” and a “Hatch Smash” knock-down stitch into this embroidery design. Stick around until the end of the video to see the stitched out results!

Don’t Have A Multi-Needle Embroidery Machine or Cap Attachments? You Can Still Embroider Hats!

If you have a flatbed or single needle embroidery machine, you might be wondering “can I still embroider on hats”? The answer is yes! With this creative workaround. Why not instead use custom embroidery patches and attach them to the cap?

Click here to see our new patch-making methods to help you easily create custom patches and get the best results possible.

Patches include a crisp merrowed edge, mimicking using a “merrow machine.” Inside these merrow edges, you can insert designs or lettering to easily create a personalized patch with any material of your choice. These patches can then be easily attached to your cap when using Post-Patch Iron-On Seal. Click here to see our suggested supplies and materials to use to create unique professional-looking patches for the best results on your caps.

Conclusion: Embroidering Hats Is Easy Using These Tips & The Right Software

Embroidering on hats can be both fun and profitable. Don’t forget it’s easiest to embroider on a cap when you have a cap frame and multi-needle. Utilizing the sides and backs of caps can provide coverage around the cap. That should satisfy even the most demanding of customers. Just be sure to follow the tips outlined above. As we know, hooping a cap can be difficult, but using the proper hooping accessories will make a world of difference! Follow our steps, and it’ll take away your frustration.

Remember the most important aspect of embroidering a hat—the embroidery! Ensure the design you stitch out is created for hats to avoid any troubles. If you want to create your designs, remember to use the bottom-up, center-forward rule. Creating designs for caps has never been easier with Hatch embroidery software’s impressive features. Click here for a free 30-day trial to help transform your dreams into reality with professional results.

Please note: This article was written by both John Deer & Steven Batts. Steven Batts, a consultant with over 23 years of experience in the embroidery industry, owns Righteous Threads, Greensboro, N.C., which offers digitizing, embroidery, and machine maintenance services. Steven regularly leads seminars at ISS shows and is an industry speaker and consultant.

I’ve never had a problem with structured caps but sometimes have a hard time hooping unstructured caps. Any suggestions?

Gгest delivery. Great aгgսments. Keep up the good wοrk.

Thank you, glad you enjoyed the article!

I’ve managed to find a hat hoop to suit my Brother NQ3500D single needle machine. Proper preparation is definitely needed to ensure the designs stitch out properly.

Your book, Digitizing Made Easy, provides such useful information and gave me so much more insight into design layout, stitch types and stitch lengths (which I’d never even considered changing from default before). My embroidery has improved dramatically.

Thank you.

I couldn’t agree more, preparation is key.

Thanks for the kind words Graham, I’m glad you found the book useful!

I appreciate you taking the time to leave some positive feedback.

Graham, Can you tell me what hat hoop you found for your Brother NQ3500D and where to buy it? I bought my mom this machine a couple of years ago and she just recently told me she’s like to have a hat attachment because all three of my sons play baseball and she’d like to make hats with their team logos. Thank you.

I’m really struggling with structured caps. They tend to “bounce” heavily even after over lowered the speed as low as it will go and the design winds up off every time. The unstructured caps I have no issues with what so ever. Any advice or input to combat this? I’ve about ruined two customer hats trying to get it to work when my trial run on an unstructured cap worked perfect.

Hey Callie,

I know within the spare parts on my Bravo Enterprise and Redline 1501 embroidery machines, they both provide an optional needle-plate that is raised slightly to account for the curve on a structured cap. I’ve found that when I change to the raised needle plate it reduces the bounce. Hope that helps!

Ili have a Toyota and I seen to only be able to stitch a 3.5inch diameter, if its any bigger my machine says limit error. How do I do a larger area of stitching on the front of a cap?

Hi Joanne,

Every machine differs in regards to the “sewing field area” on a finished hat. If it is reaching the manufacturers specs then unfortunately you cant really do much to increase the area.

Hi Joanne – I am having the same issue with my Brother PR650e when using the cap hoop. Since the hoop turns, I would think we would have a wider length than 3.5″. I’ve watched videos using the cap hoop and the same machine and they do have this ability, so I’m not certain why I am having this issue. Did you happen to find an answer? Thanks!

First of all, great article! Thanks for taking the time to put this information out there!

Second, I have a standard fitted baseball cap that I would like to embroider starting next to the centered team logo, and going all the way to the center back. A lot of places I contact say they are unable to embroider along the sides. Do you know of an embroidery cap business in NY who’s capable of doing this?

Thank you,

My pleasure Vince, glad you enjoyed it 🙂

Unfortunately no, I don’t have a specific recommendation for you in NY. Best of luck in your hunt & happy stitching.

Greetings from Colorado! I’m bored to death at work so I decided to check out your blog on my iphone during lunch break. I enjoy the info you present here and can’t wait to take a look when I get home. I’m shocked at how quick your blog loaded on my phone .. I’m not even using WIFI, just 3G .. Anyhow, awesome site!

Glad you enjoyed it and thanks Vurtil! Happy stitching 🙂

Thanks on your marvelous posting! I really enjoyed reading it, you are agreat author.I will be sure to bookmark your blog and will come back at somepoint.

You actually make it seem so easy with your presentation but I find this topicto be actually something which I think I would never understand.

We all start somewhere 🙂 Once you master the basics moving onto things like caps isn’t as difficult as you may think.

This is my first time visit at here and i am actually impressed to read everthing at oneplace.

Glad to hear you enjoyed the article 🙂

We’re a group of volunteers and starting a new scheme in our community.Your web site provided us with valuable info to work on.

Glad to hear that 🙂

Hat hooping on my Brother 10 needle seems to be ok, but when embroidering on any of the hats that have the buckram my needles break repeatedly. Should I be using different needles?

Hi Richard,

You could try titanium needles as they are supposedly stronger. Those types of hats are very stiff, especially in the center seam. Designs digitized should take into account lessening density in those hard areas.

I do own two ten needle machines and to be honest, very rarely use them for caps. I find them to be very limited in design size (peak hits the back of the machine) and the stepper motors are not as strong as my Melco, Redline or ZSK. Might be another reason for needles breaking on laminated caps.

Way cool! Some very valid points! I appreciate you penning this article and also the rest of the website is really good.

Thanks, glad you’re enjoying it 🙂

My spouse and I absolutely love your blog and find almost all of your post’s tobe precisely what I’m looking for.

I’m very happy to hear that, thanks for the kind words!

Needed to compose you a very little word to thank you yet again regarding the nice suggestions you’ve contributed here.

Thanks for reading!

Good day John

I am a begginner.

I am very much intrested in logo embroidering, and i am using a brother PE550D, all you videos are shown from very big machines. May i kindly request a short video on how to embroider caps using this kind of machine

Hi Rebecca, unfortunately we do not have this machine to demonstrate for you, we suggest to contact your dealer.

Hi John, I work as an Embroidery Designer and the company I work for have recently added caps into our product repertoire! I have read lots regarding the ‘bottom to top’ and ‘inside out’ rule – for the cap embroidery files should text be on an arc baseline for it to appear straight when the cap is worn? As we have had some caps where the text on a straight line looks to be lifted on one side after stitching – could this be as a result of not originally using the ‘inside out’ rule or should text be on an arc baseline? Many thanks.

Hi Ellie, generally, bottom-up inside out assists with reducing design movement on the curved surface. Hooping tightly where the crown meets the peak is also key. I suggest placing the cap on the head of a garment steamer right before hooping. It will soften the laminated buckram for a tighter fit.