Your embroidery machine is stitching its little heart out, then you turn away for a second and…. Whirrruuuuuuuuuh. Total silence as your machine comes to a stop!

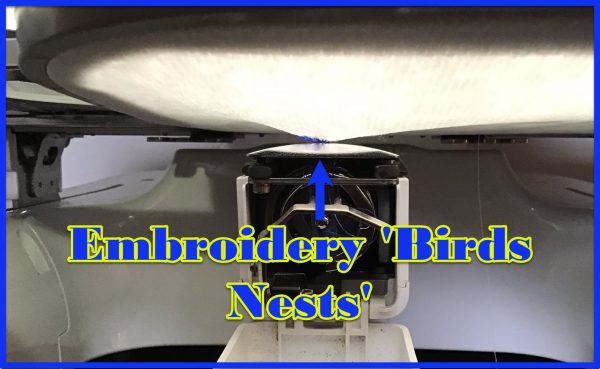

From the top, it looks fine, but when you try to remove the hoop from the machine, it’s stuck. When you try to look underneath, all you see is a big tangle of thread holding it together. What is this? How did it get there, and how can you prevent this????

Birds’ nests are cozy homes for birds, but they don’t evoke the same warm feelings in embroidery.

Don’t believe me? Ask a group of embroiderers, “Who here has ever had a Birds Nest”? Watch all the hands go up!

When they hear those words, their faces display a combination of sourness and discomfort. It’s as if they are sucking on a lemon and experiencing constipation.

In embroidery, “Birds Nests” is like saying a bad word.

What is Birds Nest Embroidery & Why Does it Happen?

A bird’s nest is bunching up of thread on the underside of the stitching. From above, it appears good, but it gets stuck in the bobbin hook and eventually halts the machine.

Incorrect insertion or threading of the bobbin or top thread causes a bird’s nest. Either way, an imbalance of tension causes it.

Remember that sewing and embroidery machines use a lock stitch that works best when both threads pull equally on the other. Think of it like shaking hands.

If one person pulls a lot, it forces the other to reach out. If you pulled someone’s hand hard and let go quickly, they would fall backward without anything to support them. It is just like thread tension.

When the thread is pulled tightly or changes suddenly, the excess thread is released from the other part of the stitch equation. This excess thread then moves around the bobbin case or the hook. With all that spinning of the hook, it is not long before you find thread nesting under the fabric.

What causes bird nesting on embroidery machines? Bird nesting occurs when:

- The top thread was threaded with the presser foot down, all the tension discs are locked, and your thread cannot get between the discs.

- You bypassed the take-up lever on the home machine – the thread has no way to be drawn through the tension discs.

- If the bobbin thread is not secured, it can freely spin. This spinning can create a tangled mess. This tangled mess is called a bobbin bird nest.

- Your bobbin is backward, be sure to check your manual. Putting your bobbin backward can allow it too little tension.

- Dirty or poorly maintained machines. Keep your machine and bobbin case free and clean of dirt and grime.

- Burrs on needle plate which can catch a thread.

- The orientation of the needle is wrong; remember that needles have a front and a back.

- Bobbin tension needs adjustment (always consult your manual before changing bobbin tension)

- Flagging occurs when a commercial frame bounces, or the garment pulls on the hoop on any machine.

A side note about tension. On a commercial machine, you should not need to adjust the tension.

A properly adjusted tension may mean you never adjust the top tension knobs. You can adjust the bobbin case tension one-quarter turn at a time, but that should be a last resort. Most malfunctions like this happen because of bad maintenance or a design that doesn’t let the thread fix itself.

I encountered some big problems with tangled thread that stuck and wouldn’t come off the embroidery machine. On rare occasions, I’ve seen the garment “pop” out of the hoop. If you notice this, the clothing will likely be ruined because the fabric has been torn.

Bird-nesting can occur due to other reasons. If you thread the upper thread incorrectly. If you do not follow the “guides” properly, or if the thread jumps out of the take-up lever. This will pretty much guarantee a buildup of thread.

The material can experience extreme ‘flagging if you loosely hoop your items.’ I prefer securely hooped items over floating ones on a hoop because hooped items always have better quality.

Mechanical issues may be more prevalent with commercial/tubular machines. If your rotary hook timing or needle bar height is incorrect, it can cause more bird nesting problems.

When I used to do the general repairs in our multi-head factory, an operator would come to me complaining that the machine was creating birds’ nests. I’d look them in the eye and say, “You hit a frame, didn’t you?”. The answer was generally always yes… unless they lied, of course.

So, two questions need to be answered:

How Do You Prevent Embroidery Thread From Bunching Under Fabric?

This sounds so easy, but it can be easy to forget.

- Keep your machine clean, and remove stray threads.

- Because it’s easy to get distracted, you should take time when loading bobbins and prevent incorrect threading. Make sure the presser foot is up to disengage the tension discs.

- Always do a visual check of your thread path; trace with your fingers

- Use good quality thread and needles

Preventing bird nests does come from prevention, pure and simple. Slow down when threading or inserting bobbins; read the manual if the machine is new to you.

How Do I Fix Thread Nesting On My Embroidery Machine?

Carefully and with the right tools. If the item hasn’t torn the fabric or made a hole, you can probably fix it. But don’t start “manhandling” the situation by pulling on the hoop aggressively.

Try to gently create a bit of space between the bobbin plate and the hoop, and then use your “tools” to do the rest of the job.

If you can get the hoop off without disrupting the garment, you’re back in business quickly!

- Don’t pull or tug

- Don’t start cutting without knowing what is happening underneath

- Don’t unhoop if you don’t have to

When you pull, you can tear fabric or existing embroidery or hurt your machine. Before you do anything, pause and look at the underside. Carefully lift the hoop and see how much thread you are dealing with.

There are two ways to clear bird nests. One way is by cutting threads and removing the hoop. The other way is by slowly picking out tightly packed threads from the needle plate.

There are “bird’s nest toolkits,” with tweezers and a knife to cut away threads. The trick is always to keep your knife below the hook to cut against the hook and not the fabric. Remember that cutting the fabric damages the garment.

You can use a cheap metal fork to flatten the prongs with a hammer. This will help you slide it under the fabric and over the needle plate. You can then more safely cut the threads. Always beware of scratching the needle plate.

Do not try to saw apart the mass of threads all at once… patience will be your friend. Just a few at a time until you can get your garment safely free of the machine. You cannot remove the nest with the garment and hoop in place.

Leave the garment hooped if you need to continue stitching if possible.

After removing your garment, you may discover the nest on the needle plate. However, extracting the bobbin or bobbin case could prove challenging. Pick out the threads one by one very carefully until you can reduce the nest enough to remove it. After you have cleared it, check the needle plate and/or bobbin case for damage and replace it.

On to the garment!

You have two choices…

- To remove stitching, cut loops on the back and pull the remaining threads from the top. You must restitch this or think of another way to cover the damage.

- Trim the nest so that only short (1 cm/.25 in) tails remain and secure with an iron-on-stabilizer. Although the threads may not stay put when washed, you can save them for items you don’t use often.

Conclusion: Thread Nests Aren’t The End Of Your Embroidery

Bird nests are unfortunate occurrences but not the end of your embroidery project! Keeping your machine clean and threading properly reduces the chance of a nest popping up (or down) in your stitching. If a nest should happen, there are ways to salvage your garment.

It is really a nice and helpful piece of information. I’m glad that you shared this helpful info with us. Please keep us informed like this. Thanks for sharing.

My pleasure, glad you enjoyed it!

Thanks for the info. Know more about bird nesting now than ever

Glad to have helped Gary, thanks for reading!

My nq1700e was bird nesting. I cleaned the race area, changed bobbin and re thread the machine to no avail. Took it to a reputable brother repair shop , they said it was mechanical error. Brought it home at approximately 24000 stitches it started bird nesting again. Repeated all the above again but to no avail. Any recommendations. I am ready to scream as you can imagine

Hi Marcia, sorry, the repetitive birds-nests you are describing are most likely a mechanical issue with relation to timing of the needle and bobbin case. Back to the shop 🙁

Thank you for your very thorough explanation of birdnesting causes. As my skills have improved, I thankfully don’t have them much anymore. (Knock on wood.)

Great to hear! Thanks for reading 🙂

nice to know that the item can be fixed. great article

Thanks for reading Rosie 🙂

Birds nests are the ABSOLUTE worst. Thanks for the good tips.

We couldn’t agree more! Thanks for reading

This was a very knowledgeable read over my morning coffee. Thank you so much. So far 🤞my bird nests have been fixable with careful monitoring. Thank you so much. Love these tips snd tricks

We’re happy to help Helen! Nothing goes better with embroidery than coffee 😛